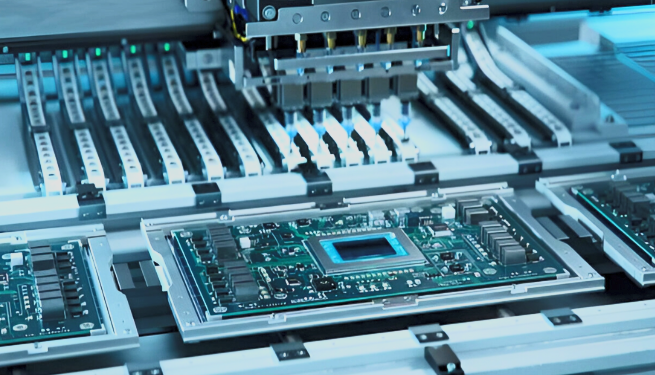

In today’s fast-evolving electronics industry, complex PCB assembly has become essential for devices that demand high performance, miniaturisation, and reliability. From aerospace systems to medical instrumentation and automotive electronics, the complexity of printed circuit board (PCB) designs continues to grow as technology advances. Manufacturers must now integrate multiple layers, fine-pitch components, and intricate routing into compact layouts—all while maintaining exceptional quality standards.

What Is Complex PCB Assembly?

Complex PCB assembly refers to the manufacturing and assembly of circuit boards with challenging designs, intricate layouts, and high component density. These PCBs often involve multilayer configurations, advanced materials, and mixed assembly technologies such as Surface Mount Technology (SMT) and Through-Hole Technology (THT).

A complex PCB might include microvias, blind or buried vias, fine-pitch BGAs (Ball Grid Arrays), and high-speed signal paths. Such features require precise engineering and high-end machinery to ensure accurate alignment, consistent solder joints, and optimal electrical performance.

Key Features of Complex PCB Assembly

1. Multilayer and High-Density Interconnects (HDI)

Complex PCBs frequently feature multilayer or HDI structures to accommodate multiple signal layers, ground planes, and power distributions. This enables efficient routing of signals while maintaining signal integrity in compact spaces.

2. Fine-Pitch Components and Miniaturisation

Modern electronics rely on ultra-small components like micro BGAs and chip-scale packages. Complex PCB assembly ensures precise placement and soldering of these delicate components without short circuits or misalignment.

3. Mixed Technology Integration

Many advanced applications combine SMT, THT, and even embedded component technologies on the same board. Skilled engineers and advanced assembly lines are required to handle these diverse technologies efficiently.

4. Stringent Quality and Reliability Standards

Given the critical nature of applications such as defence, automotive, and medical electronics, complex PCB assemblies are subject to rigorous inspection and testing. Methods such as Automated Optical Inspection (AOI), X-ray inspection, and functional testing ensure 100% reliability before delivery.

The Process of Complex PCB Assembly

Producing complex PCB assemblies demands precision, advanced equipment, and experienced technicians. The process typically involves:

- Design and DFM Review:

Before production, Design for Manufacturability (DFM) reviews identify potential issues such as insufficient spacing or improper via placement. - Solder Paste Application:

A laser-cut stencil ensures accurate solder paste deposition on fine-pitch pads. - Component Placement:

High-speed pick-and-place machines handle thousands of tiny components with micron-level precision. - Reflow and Wave Soldering:

Components are soldered using carefully controlled temperature profiles to prevent overheating and ensure solid joints. - Inspection and Testing:

AOI, X-ray inspection, and in-circuit or functional testing confirm the board’s electrical and mechanical integrity. - Final Assembly and Packaging:

Once verified, the boards are cleaned, coated, and packaged for shipment or integration into the final product.

Applications of Complex PCB Assembly

Complex PCB assemblies are used in sectors that require superior performance, compact design, and absolute reliability. Common applications include:

- Aerospace and defence systems

- Medical devices and diagnostic equipment

- Telecommunications infrastructure

- Industrial automation systems

- Automotive electronics and electric vehicles

- High-speed computing and networking devices

Each of these applications demands specific material choices, impedance control, and thermal management techniques that only advanced PCB manufacturers can provide.

Challenges in Complex PCB Assembly

While the benefits are immense, complex PCB assembly is not without challenges. Handling high-layer counts, ensuring signal integrity, and maintaining consistent quality across mass production are demanding tasks. Manufacturers must also account for heat dissipation, power management, and miniaturised solder joints, all of which require expert engineering and top-tier manufacturing capabilities.

Ensuring Reliability in Complex PCB Assembly

Reliability is the hallmark of a well-manufactured PCB. To achieve this, manufacturers employ state-of-the-art automation, real-time quality monitoring, and traceability systems throughout the production line. Each PCB undergoes extensive validation to meet international standards such as IPC-A-610 and ISO certifications.

Partner with Experts in PCB Assembly China

Choosing the right manufacturing partner is crucial for projects that involve complex PCB assembly. Collaborating with a trusted PCB assembly China expert ensures access to advanced equipment, skilled engineers, and cost-effective production without compromising quality. By leveraging their experience and precision capabilities, you can achieve consistent performance and reliability across every build—no matter how complex your design.